Xian, Shanxi Jan 26, 2026 (Issuewire.com) - The global industrial landscape has witnessed a significant shift toward specialized fastening and sealing technologies, driven by the increasing demands of modern infrastructure and energy sectors. Following a series of successful international trade engagements over the past few years, industry leaders are once again preparing to convene at prestigious forums. Building on the momentum of previous high-profile exhibitions where advanced hardware solutions took center stage, the upcoming Kaztoolexpo is set to be a pivotal event for Central Asian markets. As a prominent OEM EPDM Flat Metal Washer Producer From China, Fasto Industrial Co., Ltd. is preparing to unveil its latest sealing innovations. EPDM rubber washers, known for their exceptional ozone resistance and weatherability, serve as a critical barrier in mechanical assemblies. By combining ethylene propylene diene monomer with robust metal backings, an EPDM flat metal washer provides a dual-function solution: the metal distribution of load and the rubber's airtight, watertight seal, making it indispensable for long-term structural integrity in fluctuating climates.

Strategic Preparations for Kaztoolexpo

Exhibiting at Kaztoolexpo represents more than just a commercial showcase; it is a commitment to the regional development of construction and industrial maintenance in Kazakhstan and neighboring territories. In the preceding exhibition cycles, the focus remained largely on basic fasteners, but the upcoming year marks a transition toward integrated "sealing and fastening" systems. Fasto has dedicated months to refining its exhibit, focusing on the synergy between metal substrates and high-grade elastomers.

The preparation involves rigorous technical validation to ensure that the products displayed meet the specific environmental challenges of the region, such as extreme temperature variances. Engineers and product specialists have curated a selection of customized components that highlight the adaptability of the EPDM flat metal washer producers manufacturing line. For attendees, the booth will function as a technical hub where the physics of torque, sealing pressure, and material longevity are demonstrated through real-world applications. This proactive approach ensures that the solutions presented are not merely off-the-shelf items but engineered responses to complex engineering hurdles.

Engineering Excellence in Sealing Solutions

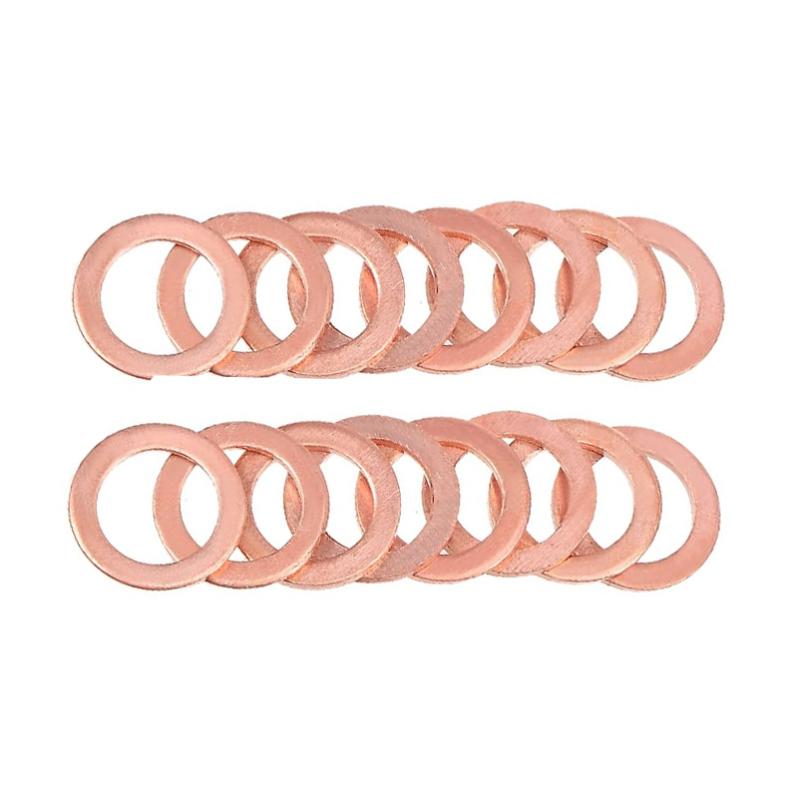

The technical superiority of an EPDM flat metal washer lies in its composite nature. These components are designed to bridge the gap between rigid metal surfaces, preventing leaks while absorbing vibrations. In the context of "Reliable Sealing Solutions," the application scenarios are vast, ranging from roofing systems where water ingress must be avoided at all costs, to heavy machinery where hydraulic seals are paramount.

Analysis of modern fender and flat round washers reveals that the bonding process between the metal and the EPDM layer is the most critical factor. A high-quality EPDM flat metal washer utilizes a vulcanization or precision adhesive process that prevents the rubber from delaminating under high torque. Whether using stainless steel or carbon steel as the base, these washers offer a cushioned interface that protects the surface of the fastened material from marring or scratching. For instance, in solar panel installations or curtain wall assemblies, the use of an EPDM flat metal washer ensures that the expansion and contraction of materials do not compromise the waterproof seal, thereby extending the lifecycle of the entire project.

Precision Manufacturing and Customization

More On Bestofnewsupdates ::

- Atua AI Deploys Smart Workflow Tools to Optimize Protocol-Level Operations

- Danielle Antoinette Naeff, Recognized by BestAgents.us as a 2025 Top Agent

- Bradley Vercosa Unveils New Personal Website Highlighting 30+ Years of Restoration Expertise

- Unlocking Europe's Pharma Potential: How WuXi AppTec Bridges the Innovation-to-Market Gap

- The Strategic Advantage: Sourcing from a Recognized Global TOP 10 Beverage Beer Equipment Services Manufacturer

As a specialized EPDM flat metal washer producer, the ability to provide bespoke dimensions is a core competitive edge. Standard sizes like M6 through M24 are common, but many industrial projects require specific outer diameters and thicknesses to accommodate unique load distributions. The production process involves precision stamping of the metal platebe it square or roundfollowed by the integration of the EPDM gasket. This ensures that every EPDM flat metal washer maintains a uniform profile, which is essential for automated assembly lines where consistency determines the speed and quality of production.

A Comprehensive Approach to Fastening Systems

The expertise required to produce high-end sealing components naturally extends into a broader portfolio of precision hardware. The transition from a specialized EPDM flat metal washer producer to a comprehensive provider of bimetal self-drilling screws and diverse fasteners is a testament to technical depth. Bimetal screws, for example, represent a pinnacle of fastener engineering, combining a hardened carbon steel point for drilling with a stainless steel body for corrosion resistance. This dual-material approach mirrors the philosophy behind the EPDM flat metal washer, where different materials are unified to achieve a performance level that a single material cannot provide.

Fasto's manufacturing capability encompasses a vast array of rivets, bolts, anchors, and threaded rods. Utilizing materials such as titanium, copper, and various grades of stainless steel, the production lines are equipped to handle complex metallurgical requirements. The integration of advanced finishesranging from ruspert and dacromate to hot-dip galvanizingensures that even a simple EPDM flat metal washer can survive the most aggressive coastal or high-load environments.

Quality Assurance and Technical Reliability

In the realm of global construction, reliability is verified through data. Adhering to ISO 9001 standards, the production cycle includes multiple stages of in-house quality control. Every batch of products, including each EPDM flat metal washer, undergoes testing for tensile strength, torque capacity, and coating thickness. One of the most significant risks in high-strength steel fasteners is hydrogen embrittlement; by maintaining strict control over the baking and plating processes, these risks are systematically minimized.

The provision of detailed technical reports for each order provides engineers and project managers with the necessary confidence to specify these components in critical infrastructure. This transparency in manufacturingcovering everything from the raw material's chemical composition to the final performance metrics of the EPDM flat metal washerestablishes a foundation of trust. It is this commitment to "Complete Fastening Solutions" that allows the company to act as a single-source partner for complex global projects, ensuring that every joint and seal is backed by rigorous engineering.

Future Perspectives in Industrial Fastening

As the industry moves toward more sustainable and durable construction methods, the role of specialized producers becomes increasingly vital. The synergy between high-performance fasteners and reliable sealing components like the EPDM flat metal washer will continue to define the standards of modern building science. By focusing on innovation, material science, and customer-centric engineering, the goal remains to provide the "Reliable Sealing Solutions" that the market demands.

The upcoming showcase at Kaztoolexpo will serve as a platform to discuss these advancements with global partners. Whether it is through the development of new protective coatings or the optimization of the EPDM flat metal washer producer's custom capabilities, the focus remains steadfast on enhancing the safety and longevity of the built environment.

For more information on the full range of products and technical specifications, please visit the official websit: https://www.fastoscrews.com/.

Media Contact

Fasto Industrial Co., Ltd.

+86-029-81165337

Room A-907, Greenland Center, NO.9 Jinye Road, Yan Ta District, Xi'an, China

Source :Fasto Industrial Co., Ltd.

This article was originally published by IssueWire. Read the original article here.